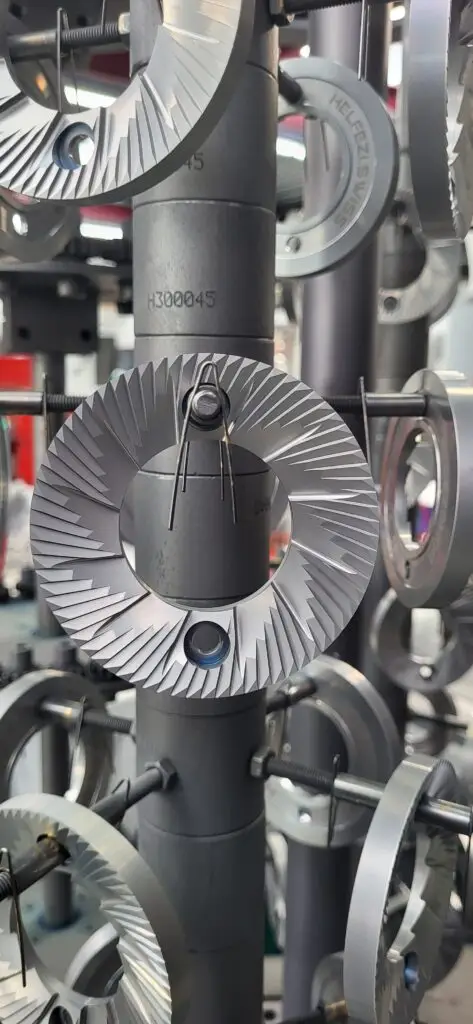

High precision and durable Swiss grinding burrs.

Helfezi grinding discs have exceptionally good edge sharpness and in combination with the processing method and coating performing with excellent cutting behaviour and longevity

Discover the latest standards with long-life special-coatings and proven grinding-geometry. Made in Switzerland.

65mm TDC coated

- Fits in K30, E65 models, Pratica, Luna, DC1

- Setting for Espresso

- Lifespan of approx. 5 tons on espresso setting

- Packing in solid Helfezi box

- Gross weight per set: 280g

80mm TDC coated

- Fits in 804/807 models, Alba and E80 grinders

- Setting for Turkish / Espresso

- Lifespan of approx. 12 tons on espresso setting

- Packing in solid Helfezi box

- Gross weight per set: 420g

Alinox 80mm set

- Fits in 804/807 models, Alba and E80 grinders

- Setting for Turkish / Espresso

- Lifespan of approx. 12 tons on espresso setting

- Packing in solid Helfezi box

- Gross weight per set: 420g

Alinox 98mm set

- Fits EK 43 models and Omnia

- Setting for Turkish / Espresso

- Lifespan of approx. 18 tons on espresso setting

- Packing in solid Helfezi box

- Gross weight per set: 580g

140mm set TDC coated (below uncoated)

- Fits in 1403 models

- Setting for Turkish / Espresso

- Lifespan of approx. 40 tons on espresso setting

- Packing in carton box

- Gross weight per set: 1420g

For uncoated burrs only: special wrapping:

Increased longevity through special-coating

Ask for promotional price

Upon your request our burrs can be dispatched globally to any country

Improved longevity by our special coating

Helfezi coffee grinding discs are crafted to meet the highest industry standards, featuring a unique Swiss coating and precision manufacturing in Switzerland.

*Discover the Advantages Coating*

1. *Exceptional Durability*

Helfezi coatings are robust, offering superior resistance to wear, corrosion, and erosion. This makes them ideal for industries where reliability and durability are essential.

2. *Eco-Friendly Solution*

Unlike many traditional coating methods, our coatings are environmentally friendly. They generate minimal waste and do not involve harmful solvents or VOCs (volatile organic compounds), making them a sustainable choice for environmentally conscious businesses.

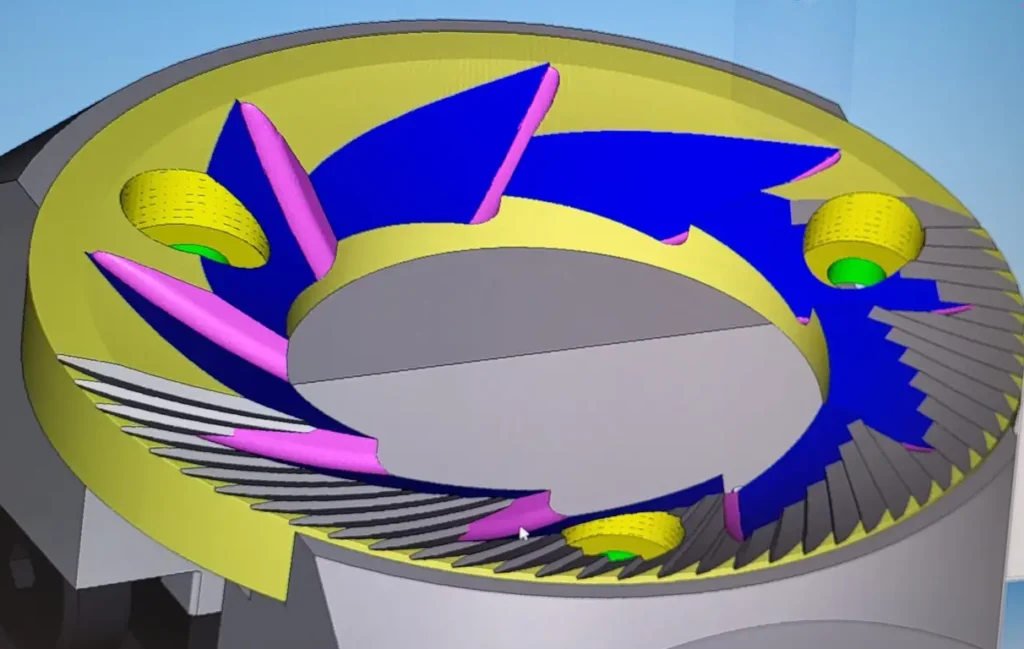

3. *High Precision Coatings*

The precise control of processes allows for the creation of coatings with exceptional precision. For instance ensuring optimal performance and protection.

*Benefits of Coating:*

– *Extremely Long Life*: Designed for longevity, contributing to reduced replacement frequency.

– *Certified for Medical & Food Use*: Safe for diverse applications, meeting stringent industry standards.

– *No Seasoning Required*: Simplifies usage and maintenance.

– *Enhanced Clarity*: Ensures a clearer visual experience in products.

– *Stable Performance*: Offers more consistent results with each use.

– *Cost-Effective*: Helps in reducing operational costs over time.

– *Corrosion Protection*: Grants resistance against corrosive environments.

*Summary*

Coatings provide a durable, versatile, and aesthetically pleasing solution that prioritizes environmental sustainability and precision.

TDC (Thin Dense Chromium) coating offers several key benefits, especially for industrial and medical equipment:

Superior Wear Resistance: TDC coatings provide a hard, protective layer that significantly reduces wear and tear, extending the lifespan of machinery and tools.

Non-Stick and Easy Release: The coating allows for smooth release of materials, which is crucial in applications like medical heat sealing and plastic molding, preventing residues and contamination.

Enhanced Corrosion Resistance: TDC acts as a barrier against oxidizing agents, protecting equipment from rust and corrosion, even in harsh environments.

Reduced Friction: The low-friction surface enables smoother, quieter, and more efficient operation, and helps minimize maintenance needs.

Improved Cleanability: The non-porous nature of TDC makes surfaces easier to clean, which is essential in medical and food processing industries.

Cost Efficiency: While initial costs may be higher, TDC coatings reduce long-term expenses by lowering maintenance, replacement, and downtime costs.

Absolute Adhesion: The coating bonds tightly to the base metal, preventing chipping, cracking, or peeling even under stress.

Thermal Conductivity: TDC coatings efficiently dissipate heat, ensuring uniform temperature distribution for sensitive processes like heat sealing.

These benefits make TDC coating a valuable solution for improving performance, reliability, and longevity in demanding applications.

OEM Grinding burrs taylor made for you

Didn’t find what you were looking for? No problem. We also design/ manufacture grinding discs according to your requirements and specifications.

Contact

Helfezi AG

Office 1-333

Freight West

CH-8058 Zurich

Switzerland

+41 44 867 5059

info@helfezi.swiss